Dynamics 365 Supply Chain Management & Finance

Dynamics 365 Supply Chain Management & Finance

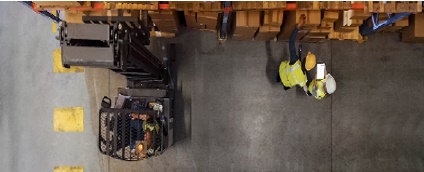

Optimize planning, production, inventory, warehouse, and transportation to maximize operational efficiency and asset productivity. Take advantage of data for robust, real-time reporting and analytics.

Over the last decade, global supply chains have seen a significant increase in disruptions for many reasons, from natural disasters to trade wars to the current global health crisis. Now is the time to get the right solutions in place to improve real-time visibility across your supply chains, so you can react faster and mitigate risk.

To improve demand forecast

- Improve end-to-end visibility in your supply chain across geographies and time zones by integrating sales and purchasing with logistics, inventory, production, warehouse, and transportation management.

- Explore partnerships with more diverse suppliers, who can improve the flexibility of your capacity while reducing reliance on single, low-cost sources.

- Integrate sales and marketing pipeline data into the planning process to better forecast demand.

- Run what-if analyses to combat changes and disruptions, exploring new suppliers, new geographies, as well as negotiations and reallocations with customers.

- Deliver cross-channel inventory visibility with realtime insight into product location and stock levels for both internal and external consumption.

To Reduce errors and Increase uptime

- Reduce costly downtime and extend the longevity of assets by performing predictive maintenance, leveraging enhanced resource scheduling, IoT, and mixed reality to keep lines running 24-7.

- Increase uptime, throughput, and quality by proactively managing shop floor and equipment operations with a real-time view of your entire production and stock using IoT.

To find more opportunity for cost saving

- Optimize fulfillment and reduce costs by synchronizing logistics across sites, warehouses, and transportation modes.

- Limit inventory storage in supply chain nodes, which can put a burden on cash flow.

- Reduce store operations costs while reinvigorating the role of the store sales environment with actionable alerts for managers and employees triggered by store activity.

- Ensure business continuity by optimizing your sourcing and fulfillment strategy with a fast and sophisticated supplier qualification process.

- Reduce cost of demand fulfillment through intelligent distributed order management and agile product fulfillment options.

Resolve issues quickly and manage products quality

Take control of change

An increase in product complexity and a rise in the breadth and depth of product portfolios have gone hand in hand with the creation of sprawling global supply chains that continue to add more and more diverse participants. Without effective and robust engineering change management processes, the modern enterprise can be hard-pressed to manage cost, maintain and improve product quality, and minimize time-to-market.

Dynamics 365 Supply Chain Management Dynamics 365 Supply Chain Management’s Engineering Change Management solution gives organizations greater control of and visibility into changes across product lifecycles. Embedded workflows provide the means to automate product release and acceptance, and they help ensure the right people are involved and prompted to take action on engineering change orders and requests.

Key Features:

- Product versioning Use engineering versions to keep the various forms of a product and its data current, clear, and visually represented in the system.

- Lifecycle management Enable detailed control of data ownership and lifecycle management, decide when and to whom to release data, and define which processes are clear to run specific items across the business.

- Engineering change requests Empower users to request product changes by submitting engineering change requests to a centralized system.

- Engineering change orders Easily identify, adopt, and implement changes in ingredients and formulations, keep all affected parties aligned, and retain a historical record of product development.

- Readiness checks Use readiness checks to ensure that all product master data has been specified before initiating the new product introduction process.

Demand forecasting

Improve demand forecasting by leveraging machine learning. Integrate cross-company sales and operations planning to minimize inventories and improve on-time delivery.

By integrating demand forecasting across Supply Chain Management, sales, and operations planning, organizations can avoid overstocking, increase inventory turns, and improve cash-to-cash cycle times while simultaneously ensuring high levels of on-time delivery to customers.

Key Features of demand forecasting

- Statistical forecast Utilize various statistical methods to create a baseline demand forecast based on historical data for warehouses, customer groups, items, customer accounts, countries, regions, and states.

- Visualize data Visualize historical data, demand forecasts, and confidence intervals to easily identify and make targeted forecast adjustments.

- Utilize “what-if” analysis Explore the impact of potential changes in plan inputs to better equip yourself to combat changes and disruptions.

Master planning

Plan supply and distribution throughout the day in near-real-time with in-memory services, ensuring that the right inventory is in the right place at the right time. Planning optimization allows companies to turn a 5-hour task into a 5-minute task, reducing lead time, increasing throughput, and improving responsiveness. Balance demand and supply in real-time Meeting customer demands is more challenging today than ever before.

Businesses need to quickly adapt to changing trends to ensure the right products are available at the right time. Bridging this gap requires intelligent planning and a real-time understanding of the materials and capacities required to complete production goals. Modern manufacturers need solutions that allow them to plan strategically, streamline processes, and hit production targets on a consistent basis.

Demand forecasting capabilities enable businesses to intelligently anticipate needs while planning tools help ensure they have the right resources—including raw materials, workforce, and machinery—to meet customer demands.

Key Features of Master Planning

- Planning optimization Consistently deliver product on time by performing production planning multiple times a day to detect and incorporate changes in demand capacity constraints.

- Demand forecasting Create intelligent, datadriven forecasts, and create measurements of forecast accuracy and adjust forecast as needed.

- Material requirement planning Determine what materials are needed and schedule order release dates based on demand to meet customer needs while minimizing material and inventory carrying costs.

- Capacity planning Optimize resource allocation based on demand and supply fluctuations in real-time to minimize overtime and improve equipment allocation.

- Inventory policies Improve inventory turns by right sizing inventory levels based on dynamically changing customer demand and capacity constraints.